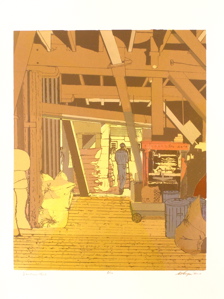

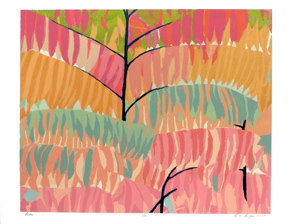

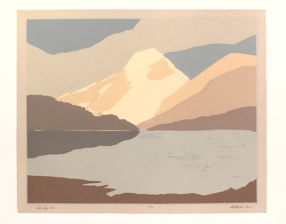

SerigraphySerigraphy is said to be the oldest form of art reproduction. Sometimes called silk-screen printing, it is a stenciling method that involves a fabric mesh screen stretched across a frame. Today, polyester mesh is used instead of silk. The paper is placed under the screen. Block-outs are applied to the screen by various methods so that only certain parts of the image will receive ink each time. The ink is placed onto the upper side of the screen and forced through the screen onto the paper by drawing a rubber squeegee across the screen.Images of various kinds can be transferred to the screen. Formerly I used photographic images from negatives. Now I use my own drawings made to print size.I usually hand-pull 10 pieces of each print edition. Each edition is unique and cannot be duplicated. My serigraphs involve up to 75 pulls and 40 colours. Printing time can be up to 140 hours. Time spent preparing the photographic image or drawing is extra.I have been doing serigraphy for almost 30 years. For most of this time, I have been fortunate to have a work area at Precision Poly Screen, an Oshawa, Ontario business that makes silk screens commercially for the automotive industry. |

|

|

|

|

|

Charles Cooper Serigraphs

subglobal1 link | subglobal1 link | subglobal1

link | subglobal1 link | subglobal1 link | subglobal1

link | subglobal1 link

subglobal2 link | subglobal2 link | subglobal2

link | subglobal2 link | subglobal2 link | subglobal2

link | subglobal2 link

subglobal3 link | subglobal3 link | subglobal3

link | subglobal3 link | subglobal3 link | subglobal3

link | subglobal3 link

subglobal4 link | subglobal4 link | subglobal4

link | subglobal4 link | subglobal4 link | subglobal4

link | subglobal4 link

subglobal5 link | subglobal5 link | subglobal5

link | subglobal5 link | subglobal5 link | subglobal5

link | subglobal5 link

subglobal6 link | subglobal6 link | subglobal6

link | subglobal6 link | subglobal6 link | subglobal6

link | subglobal6 link